In the modern logistics and warehousing industry, pallets are the backbone of material handling. Over the years, the demand for stronger, more durable, and cost-effective pallet solutions has led to the rise of a new favorite: Blow-Molded Double-Sided Pallets.

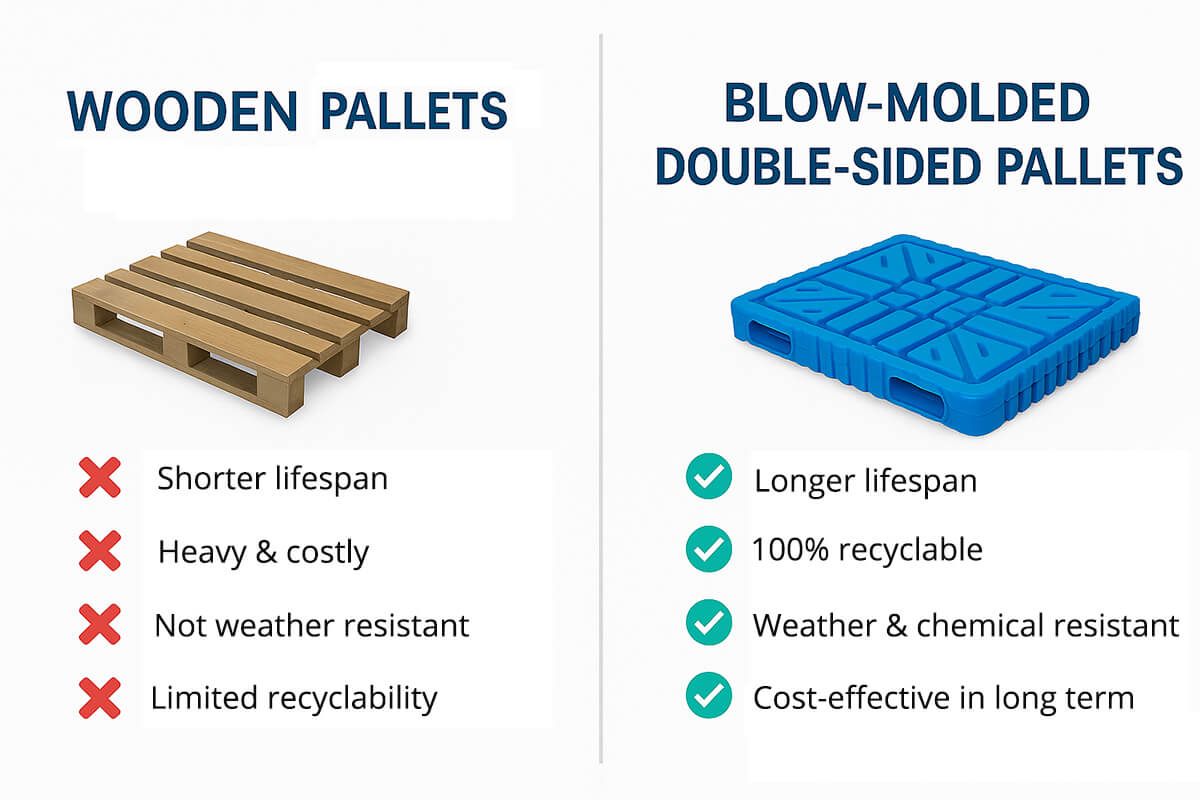

Compared with traditional wooden pallets, metal pallets, and even single-sided plastic pallets, this innovative solution is setting a new standard for high-load, long-life, and environmentally friendly pallet applications.

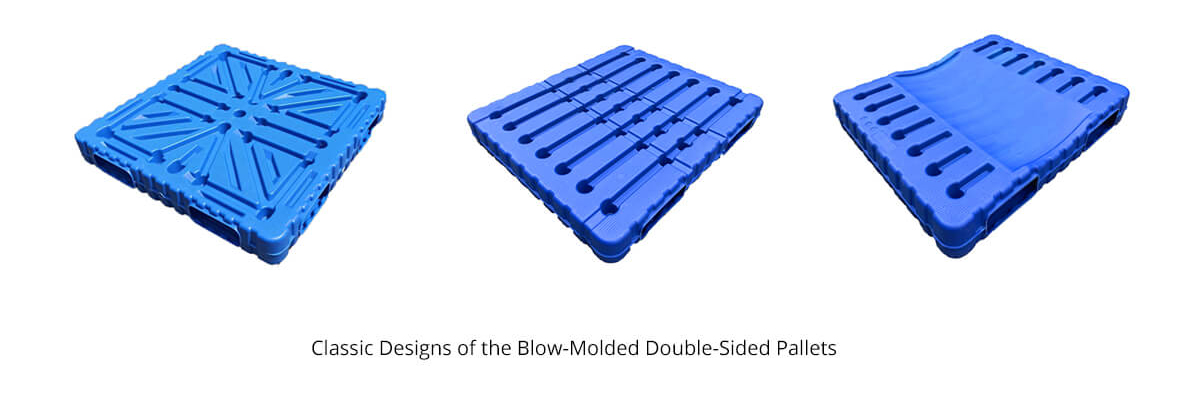

What Are Blow-Molded Double-Sided Pallets?

These pallets are manufactured using high molecular weight high-density polyethylene (HMWHDPE) through blow-molding technology. Unlike single-sided pallets, they feature a double-sided structure, meaning both sides can be used interchangeably.

They are designed with smooth surfaces with anti-slip desing for easy cargo stacking, while their dynamic load capacity generally reaches 2 tons or more. Even if one side gets damaged, the other side can still function, significantly extending the pallet’s service life.

Key Advantages of

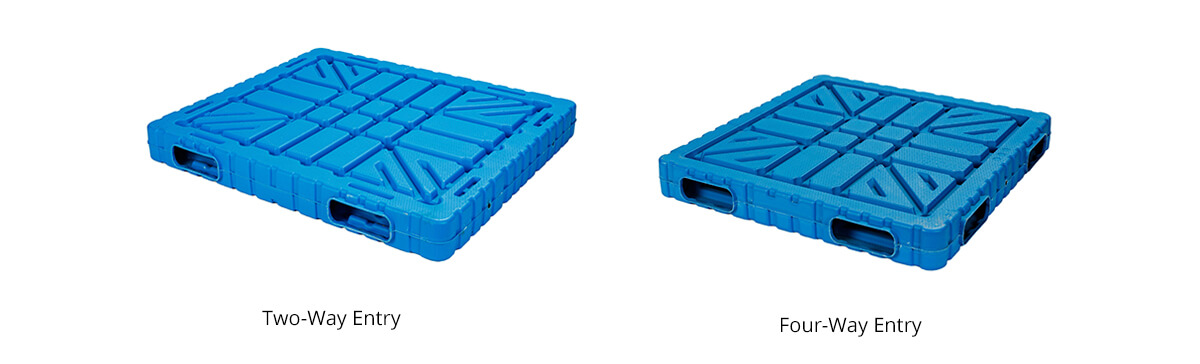

1. Versatility & Flexibility

-

Four-way and two-way entry design both available, compatible with forklifts and manual pallet jacks

-

No need to distinguish between front and back sides

-

Easy stacking and handling, even without mechanical equipment

2. Strong Load Capacity & Durability

-

Dynamic load ≥ 2 tons; static load even higher

-

Service life of over 5 years

-

Resistant to impacts, UV exposure, moisture, and extreme temperatures

3. Storage & Logistics Benefits

-

Flat surface makes stacking stable and secure

-

Maximizes warehouse height utilization and reduces racking costs

-

Widely used in chemical, heavy machinery, food, and pharmaceutical industries

4. Eco-Friendly & Cost-Effective

-

100% recyclable and sustainable

-

Lighter than wood and cheaper than metal in long-term use

-

Extended service life reduces replacement and operational costs

Zhenghao Plastics: Double-face Blow Molded Pallets

Industry Applications

Blow-molded double-sided pallets are highly versatile and can be used across a wide range of industries and materials. Some common examples include:

-

Fertilizer industry: transporting and storing bulk chemical fertilizers, often in big bags.

-

Feed industry: handling livestock and poultry feed in bags or bulk packaging.

-

Raw materials & bulk goods: suitable for resin pellets, minerals, powders, and other raw industrial materials.

-

Grain and agricultural products: storing and shipping rice, wheat, corn, beans, and other food grains.

-

Seeds and agricultural supplies: safe for stacking and transporting seed bags with high load requirements.

-

Cold chain logistics: reliable in cold storage warehouses for frozen food, seafood, and dairy.

-

Chemical industry: resistant to acid and alkali, ideal for chemical barrels and liquid containers.

-

Heavy industry: suitable for mechanical components, electronic equipment, and construction materials.

Zhenghao Plastics: Double-face Blow Molded Pallets

Why Choose Blow-Molded Double-Sided Pallets?

When companies choose pallets, three factors always matter: load capacity, durability, and cost efficiency.

Blow-molded double-sided pallets excel in all three:

-

High strength & long service life → safer operations

-

Flexible & eco-friendly → suitable for various industries

-

Lower total cost → reduces storage and transportation expenses

This makes them the preferred pallet solution for chemical, food, pharmaceutical, cold chain, and heavy manufacturing sectors.

Conclusion

Blow-molded double-sided pallets are not just another pallet option—they are a future-ready solution for modern logistics. With their combination of high load-bearing capacity, durability, versatility, and recyclability, they help businesses achieve greater efficiency while lowering long-term costs.

If your company is looking for a reliable and durable pallet system, blow-molded double-sided pallets are an investment that pays off.