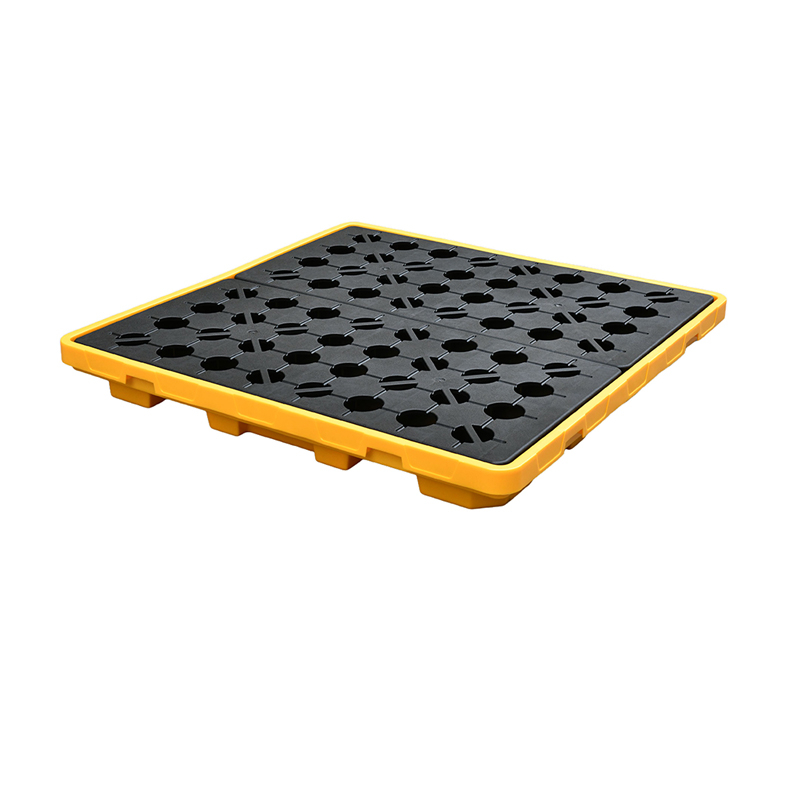

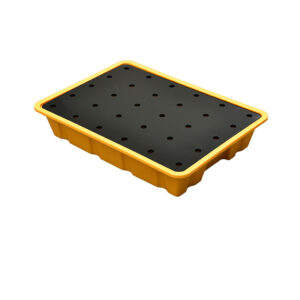

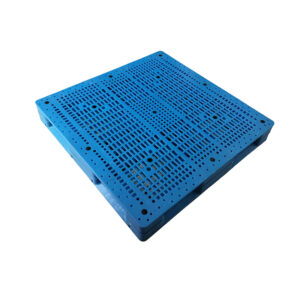

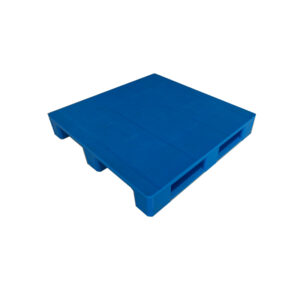

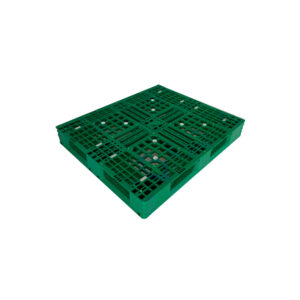

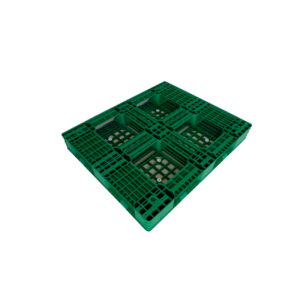

1300X1300X150 Four-Drum Spill Containment Pallets

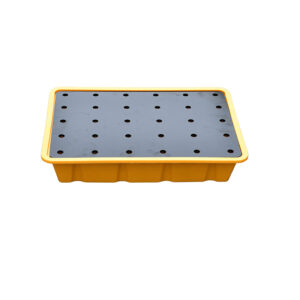

The 4-Drum Leak-Proof Plastic Pallet is designed to securely hold up to four standard 200L drums while preventing leaks and spills. Made from high-strength, chemical-resistant plastic, it ensures safe storage and transportation of hazardous liquids. Its robust, one-piece construction enhances stability, durability, and ease of handling in industrial and chemical environments.

Key Features of 4-drum Leak-Proof Plastic Pallets

-

Leak-proof design to prevent chemical spills and contamination.

-

Holds 4 standard 200L drums securely.

-

High-strength, chemical-resistant plastic construction.

-

One-piece, durable, and stable structure.

- Easy to clean and maintain, suitable for indoor and outdoor use.

Why Choose 4-drum Leak-Proof Plastic Pallets?

-

Ensures environmental and personnel safety by containing potential spills.

-

Reduces cleanup time and operational risks.

-

Lightweight yet strong for forklift and pallet jack handling.

-

Resistant to a wide range of chemicals, oils, and acids.

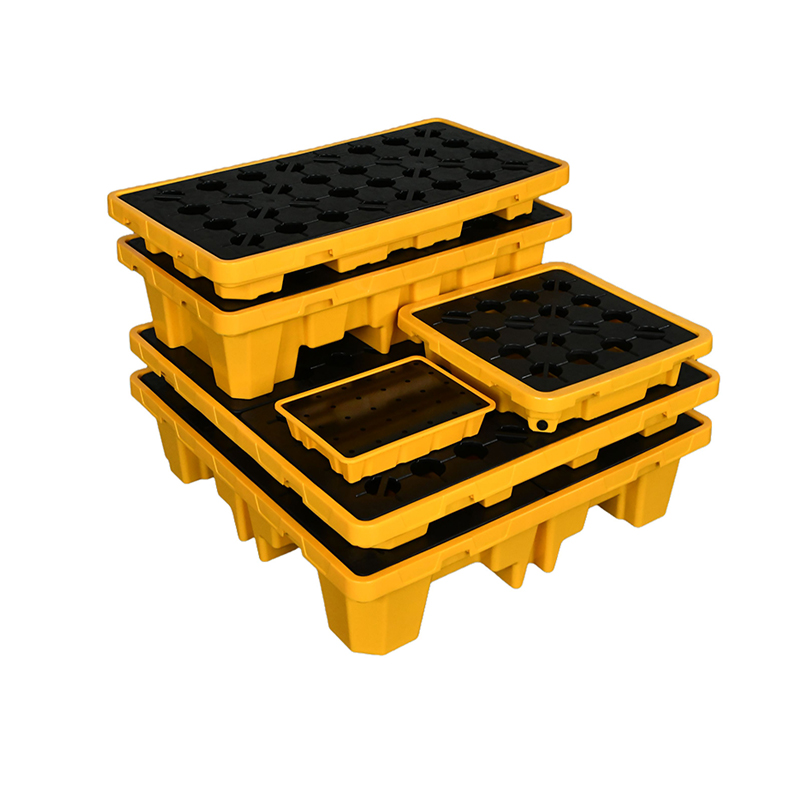

- Stackable design for efficient storage and transport.

Specs

| Size: | 1300X1300X150mm |

| Static Load: | 2700 kg |

| Dynamic Load: | 1000kg |

| Molding Method: | One-step injection molding |

| Fork Entry: | 4-way |

| Color: | Standard Color Yellow |

Other Available Sizes

Same model, multiple options to meet your needs.

| Size (mm) | Size (mm) |

| 490×355×95 | 680x680x150mm |

| 1300×680×150 | 1300×1300×300 |

| 1300×680×300 | / |

Application

-

Chemical Industry – Prevent spills and protect personnel and the environment during storage, production, and transport of chemicals.

-

Hazardous Waste Management – Safely contain leaks during storage, handling, and transportation of hazardous materials.

-

Laboratories – Capture small container spills on benches, protecting equipment and floors.

- Oil & Lubricant Storage – Secure storage of oil drums in depots, gas stations, and workshops to prevent leaks.

- Battery Storage – Ideal for acid batteries, preventing leakage and equipment corrosion.

- Liquid Transfer & Filling Operations – Minimize spillage during pouring or filling processes, protecting surfaces and machinery.

- Emergency Spill Response – Temporarily collect and contain leaked liquids, limiting spill spread and damage.