In modern agriculture, the large-scale and industrialized cultivation of edible mushrooms has become a significant trend. As an essential auxiliary tool in mushroom production, the quality and performance of plastic pallets directly affect production efficiency, mushroom bag stability, and overall product quality. Shandong, one of the world’s most important mushroom cultivation and production bases, has seen a growing demand for high-quality plastic pallets. Local manufacturers are continuously innovating in materials, technology, and design to provide products that meet strict industry standards and help mushroom farms achieve better results.

The Role of Plastic Pallets in Mushroom Cultivation

Mushroom cultivation environments are typically characterized by high humidity, high temperature, and ventilation requirements. Pallets are used in almost every step—bag stacking, air circulation, moisture retention, transport, and storage. Compared with traditional wooden pallets, plastic pallets offer superior durability, corrosion resistance, reusability, and easier cleaning and disinfection, making them the preferred choice for modern mushroom farming in Shandong.

Production Features of Mushroom Cultivation Pallets

-

High-Quality Raw Materials

Shandong producers generally use HDPE (High-Density Polyethylene) or PP (Polypropylene), ensuring excellent resistance to moisture, corrosion, and temperature fluctuations—ideal for mushroom cultivation workshops. -

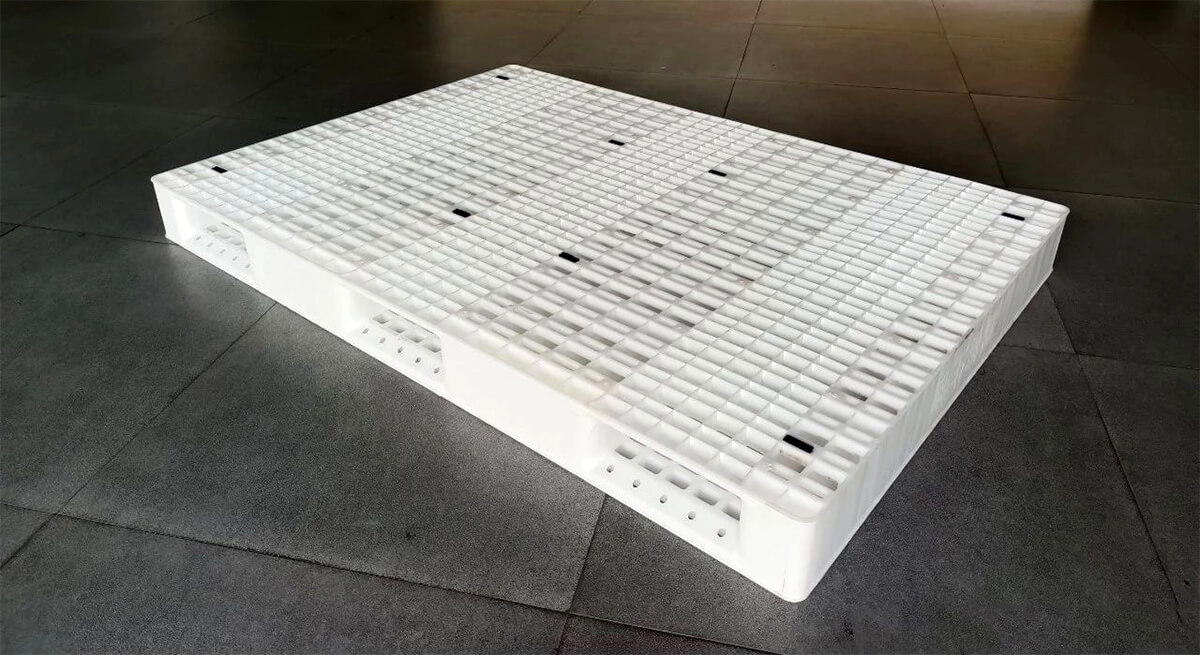

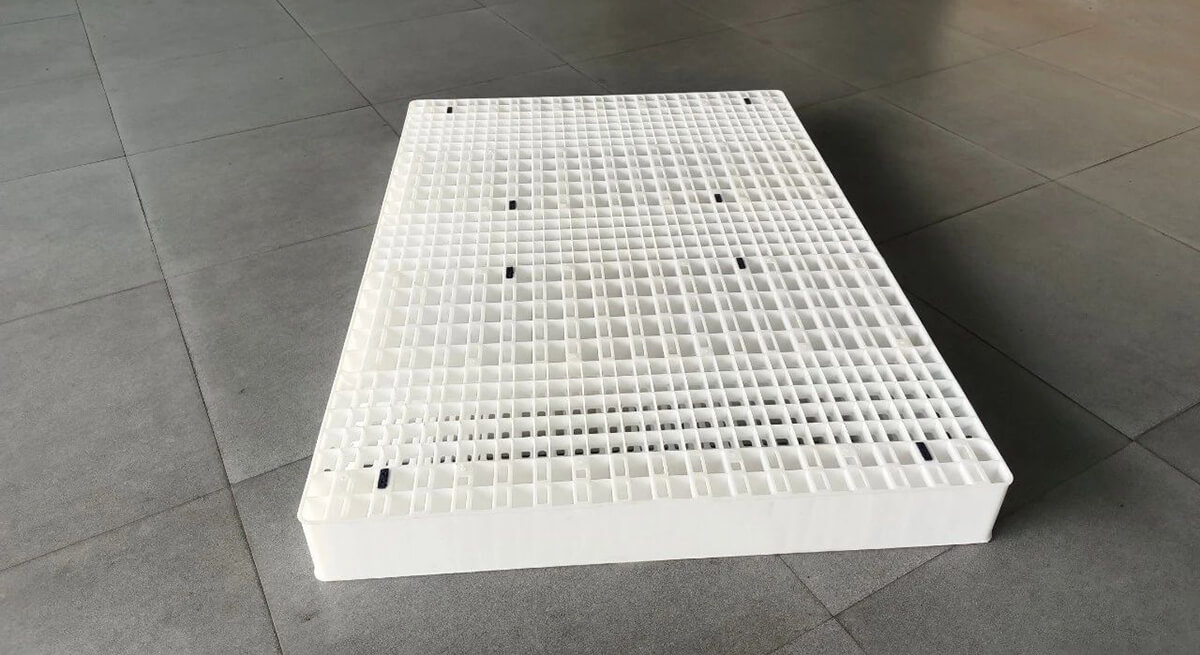

Innovative Structural Design

For example, Zhenghao Plastics (Zhpallets) has developed double-layer pallets with a load capacity of up to 200 kg, while standard pallets typically hold only 80–120 kg. This design ensures mushroom bags remain stable in hot and humid environments, significantly reducing breakage and deformation. -

Enhanced Surface Functions

Zhenghao Plastics also integrates anti-slip surfaces and anti-mold treatment, preventing mushroom bags from sliding and reducing contamination risk. In addition, UV-resistant additives extend pallet lifespan, allowing them to remain structurally stable even after prolonged sunlight exposure.

Cost Efficiency: Plastic Pallets vs. Wooden Pallets

-

Wooden pallets: A mushroom farm using wooden pallets replaced them twice per month at RMB 15 each, costing around RMB 300 monthly.

-

Plastic pallets: With high-strength pallets from Zhenghao Plastics, each unit costs RMB 30 but lasts 12 months, making the annual cost only RMB 360.

While the upfront price is slightly higher, the lifecycle cost is much lower, as the plastic pallet lasts 6 times longer and requires minimal maintenance—greatly improving overall farm profitability.

Adaptability to Different Mushroom Species

-

Shiitake: Requires excellent ventilation and humidity control. Multi-vented, double-sided pallets designed by Shandong manufacturers enhance air circulation and reduce spoilage.

-

Enoki: Requires stability and heavy load-bearing. Data shows that using reinforced thickened pallets reduces deformation rates by 40% and lowers bag breakage rates by 25% under high-humidity conditions.

Performance Comparison

-

Deformation Rate: Standard pallets ≈15%, high-performance pallets ≈5%.

-

Corrosion Resistance: Wooden pallets show visible damage after 3 months, while high-quality plastic pallets remain intact.

-

Logistics Efficiency: Plastic pallets improve load capacity by 15% and boost transport efficiency by 20% compared to traditional options.

Future Development Directions

As the mushroom industry continues to scale up, Shandong manufacturers are expected to focus on:

-

Material & Process Upgrades – improving stability under extreme conditions.

-

Diversified Designs – tailored for specific mushroom species and different production stages.

-

Sustainability & Cost Optimization – extending service life and lowering replacement frequency to support eco-friendly farming.

Conclusion

Shandong mushroom plastic pallet manufacturers are growing in strength.Companies like Zhenghao Plastics use premium raw materials and innovative designs.

Strict quality control ensures reliable performance.In mushroom cultivation, bag stacking, storage, and logistics, pallets are essential.They improve efficiency, reduce losses,

and protect food safety.

Looking ahead, suppliers will keep investing in R&D.New designs will bring stronger, cost-effective, and sustainable solutions.

Shandong will continue to support the global mushroom industry.