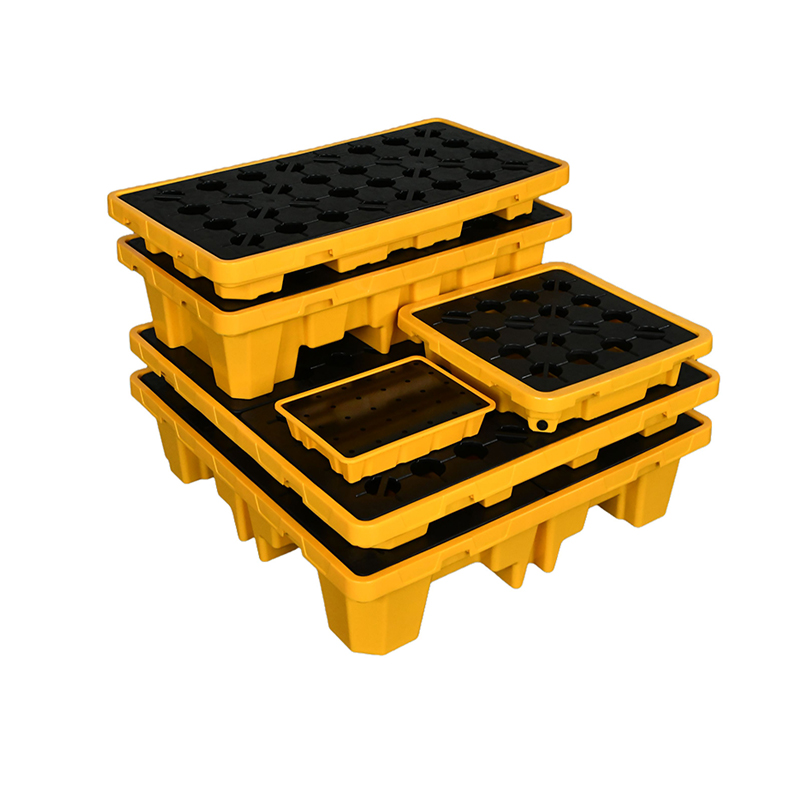

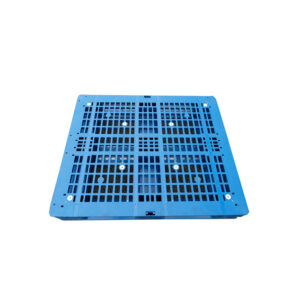

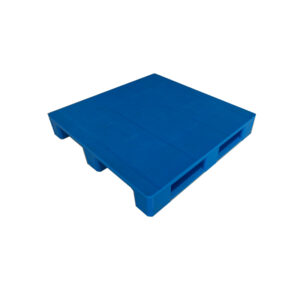

1300×680×150 Two-Drum Spill Containment Pallets

Our spill-proof plastic pallets are engineered for safe and efficient storage and transport of liquids and leak-prone goods. Featuring a seamless, one-piece design, it effectively prevents leakage, maintaining a clean and safe warehouse environment. Constructed from high-strength, durable plastic, this pallet is corrosion-resistant, moisture-proof, and reusable, making it ideal for industries such as chemical, food, and pharmaceutical.

Key Features of Two-Drum Spill Containment Pallets

-

Seamless One-Piece Design: Prevents liquid leakage and ensures hygienic storage.

-

High-Strength Material: Durable plastic with excellent load-bearing capacity.

-

Corrosion & Moisture Resistant: Suitable for chemical, wet, or harsh environments.

-

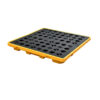

Stackable & Forklift-Compatible: Optimized for efficient warehouse handling.

- Multiple Sizes Available: Flexible options to meet different storage requirements.

Why Choose Two-Drum Spill Containment Pallets ?

-

Safe & Clean Storage: Prevents spills and protects warehouse and transport areas.

-

Long Service Life: Reusable design reduces replacement costs and environmental impact.

-

Lightweight & Easy to Handle: Designed for seamless operation with standard warehouse equipment.

-

Versatile Use: Suitable for various industries including chemical, food, and pharmaceutical logistics.

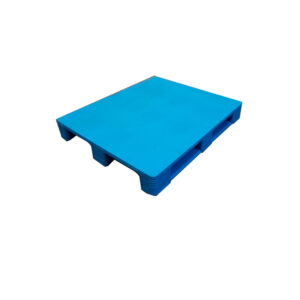

Specs

| Size: | 1300X680X150mm |

| Static Load: | 1200 kg |

| Dynamic Load: | 650kg |

| Molding Method: | One-step injection molding |

| Fork Entry: | 4-way |

| Color: | Standard Color Yellow |

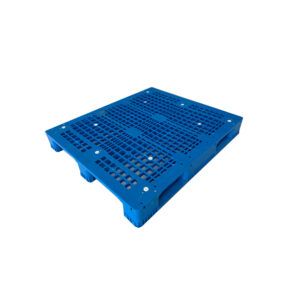

Other Available Sizes

Same model, multiple options to meet your needs.

| Size (mm) | Size (mm) |

| 490×355×95 | 1300×1300×150 |

| 1300×680×300 | 1300×1300×300 |

| 680×680×150 | / |

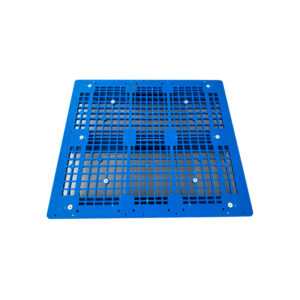

Application

-

Chemical Industry – Prevent spills and protect personnel and the environment during storage, production, and transport of chemicals.

-

Hazardous Waste Management – Safely contain leaks during storage, handling, and transportation of hazardous materials.

-

Laboratories – Capture small container spills on benches, protecting equipment and floors.

- Oil & Lubricant Storage – Secure storage of oil drums in depots, gas stations, and workshops to prevent leaks.

- Battery Storage – Ideal for acid batteries, preventing leakage and equipment corrosion.

- Liquid Transfer & Filling Operations – Minimize spillage during pouring or filling processes, protecting surfaces and machinery.

- Emergency Spill Response – Temporarily collect and contain leaked liquids, limiting spill spread and damage.